June 2013: Kickapoo Coffee For You At Wormhole

Throughout the month of June, 2013, you’ll be able to pick up the loveliness that is Kickapoo Coffee here at Wormhole, both on the pour over bar and on the retail shelf.

We’ve written about the beginnings of Kickapoo Coffee before (read it here!), so here we’ll concentrate on giving you details that will help you enjoy their coffees this month here at Wormhole. We also hope enjoying said beans will inspire you to visit their online shop, and, if you’re ever up in Viroqua, Wisc., stop on by and say hello.

Kickapoo @ Worm, June 2013: The NOTES

It’s a special month for us here at Wormhole, our third anniversary as an existing entity, and we’re celebrating with Kickapoo on June 10 with a public cupping at Wormhole.

“That’s right, Caleb [Nicholes, co-founder of Kickapoo] & company will be with us again,” says our guest coffee program manager, Canaan Vallejos. “Invite your friends, loved ones or anyone else public-related for cupping times. Cupping shizz will start around 6:30 p.m. Boom.”

On the daily grind side of things, we’re featuring Kickapoo Coffee on our brew bar:

- Ethiopia Sidama Fero: tart-like lemon zest; sweet; and a medium silky body (brew bar).

- Ethiopia Yirgacheffe Banko: tart-like lemon zest; melon sweetness; soft & sweet linger; and a light, juicy body (brew bar & espresso).

- Equador Palands: super-sweet almond butter times; floral hovering over it all; and a full, silky body (brew bar).

“These are damned lovely coffees,” says Vallejos. “We hope you all get familiar with it.”

For more on the back side of the coffee’s journey to our retail shelf, we turn to Nicholes. “It’s a weird time of year because the best of the Central American and African coffees are just arriving and we’re phasing out our South American coffees.

“We just released a couple of fresh pressed Ethiopian coffees and every year, some of our stand-out coffees at Wormhole have been direct-source Kenyans and those should be released at some point in June,” continues Nicholes, going on to make a bigger point. “The thing about coffee: freshness is the name of the game. The top roasters are working really hard to both source the highest-quality coffees and to get logistics in place to get those coffees out of the country [of origin] and into the market as soon as possible so consumers have a crack at enjoying those coffees while still in their prime. Coffee never gets better with time, only worse.”

The folks at Kickapoo and other well-regarded craft roasters take pride in how quickly they can get coffees to market with best case scenario farm-to-roaster turnaround being 2.5 (best case!) to 3-4 months–short of air freighting, which is cost- and environmentally-prohibitive. The Ethiopian fresh cop releases being served at Wormhole while supplies last are an example of this, being fairly rare, with Stumptown Coffee also serving some of them up. And, so, FRESHIES for you!!

Now, More Kickapoo For You: A New Facility!

Simply put, big changes are afoot at Kickapoo. A whole new facility is in the offing, having grown out of their 1,500-sq.-ft. space, to say the least. One positive their lack of expansive facilities brought to the table? Efficiency.

“Essentially, right now, we’re one of the most efficient roasters in the country, if I had to guess,” says Nicholes. “Our whole operation, we have about 10 employees, is situated in a 1500-sq.-ft. train depot and we are busting out of this building.”

Literally. “We have an awesome crew, but there are frustrations with working here,” says Kickapoo co-founder, T.J. Semanchin. We’re absolutely forced to be efficient and tight here. I think it will carry over to the new space, so good hybrid of bringing in new efficiencies we can’t do here, but still keeping our production flow really tight because there’s just massive efficiency in that. Fewer steps from the roaster to the rest of the facility creates efficiency. We’ve literally hit the wall in our present space.”

Finding a new spot for the roasterie? Difficult. “We’ve been thinking about a new space for the last couple of years, trying to get that space dialed in, being conscious of where we’re coming from,” says Nicholes. “The building that we’ve been in for the last five-plus years is three blocks from my house in a semi-residential area, an old historic part of town.”

Unfortunately, a deal to take over an old tobacco warehouse fell through. However, like they always do, the Kickapoo team bounced back and are moving into a new incubator space, an old factory, with other like-minded businesses (including Nicholes’ sister and her husband’s new craft soda company, Wisco Pop). “It’s the NCR (National Cash Register) Building,” says Nicholes. “They have this huge factory in town that essentially got abandoned and it was purchased by a non-profit that started up around this building to reappropriate it. It’s a 100,000-sq.-ft. building and they’re treating it as a non-profit incubator. The building is still largely unoccupied but there is a handcrafted, organic soap maker in there, a big organic farm consolidation area where they essentially buy organic produce from small scale farmers in the area and distribute it out to food co-ops in the Midwest.

“There’s going to be a sweet vibe going on,” Nicholes says of the new space. “We’re working with a designer who is hardcore creative about the concept and is working with us to come up with a design for the new roastery that would bring in a lot of the ‘old’ feel that we love. Just yesterday, we were out at a local Amish farm who they essentially are in business of reclaiming old timbers from barns in the Midwest, so we’re bringing in 100-year-old Douglas Fir reclaimed timber that was 36’ long, 1’ x 1’ and just beautiful old, red wood. There are going to be some ridiculously cool features: we’re using the same wood to craft into tasting tables in the cupping room and working with a local Amish tinsmith to have copper-topped tables with old Douglas Fir legs in an old farmhouse style that we’re really psyched on. Going to be good to have a lot more space and quiet, won’t be on top of each other. Should be an awesome energy there.”

“There’s going to be a sweet vibe going on,” Nicholes says of the new space. “We’re working with a designer who is hardcore creative about the concept and is working with us to come up with a design for the new roastery that would bring in a lot of the ‘old’ feel that we love. Just yesterday, we were out at a local Amish farm who they essentially are in business of reclaiming old timbers from barns in the Midwest, so we’re bringing in 100-year-old Douglas Fir reclaimed timber that was 36’ long, 1’ x 1’ and just beautiful old, red wood. There are going to be some ridiculously cool features: we’re using the same wood to craft into tasting tables in the cupping room and working with a local Amish tinsmith to have copper-topped tables with old Douglas Fir legs in an old farmhouse style that we’re really psyched on. Going to be good to have a lot more space and quiet, won’t be on top of each other. Should be an awesome energy there.”

If you’re not convinced of their need for a new facility at this point, here you go. If you are, this is funny anyway. “Right now I’m in the middle of my office, which is the cupping room, employee break room, lunch room, quality control room and I cannot have a phone call anywhere in this building, so we are in dire need of more space,” relates Semanchin. “We hope to be up and roasting in the new space by September. It’s the same roaster, so we’ll have everything over there installed–gas, venting, electrical–ready to bring the roaster over and fire it up–plug and play.

“We’re going to have this beautiful showcase cupping room as soon as you walk in the space, going to be screaming to brew up some tasty coffee,” says Semanchin. “We have that a little bit now, we have a cupping room, but it’s jam-packed with equipment and people. Just for work-flow, for everybody, from the office staff to the production guys, being able to do their jobs more efficiently, think the quality of work is going to improve and people’s engagement and overall well being will improve. Happy people make good coffee, for sure.”

Machinery: The Kickapoo Roaster & Data System

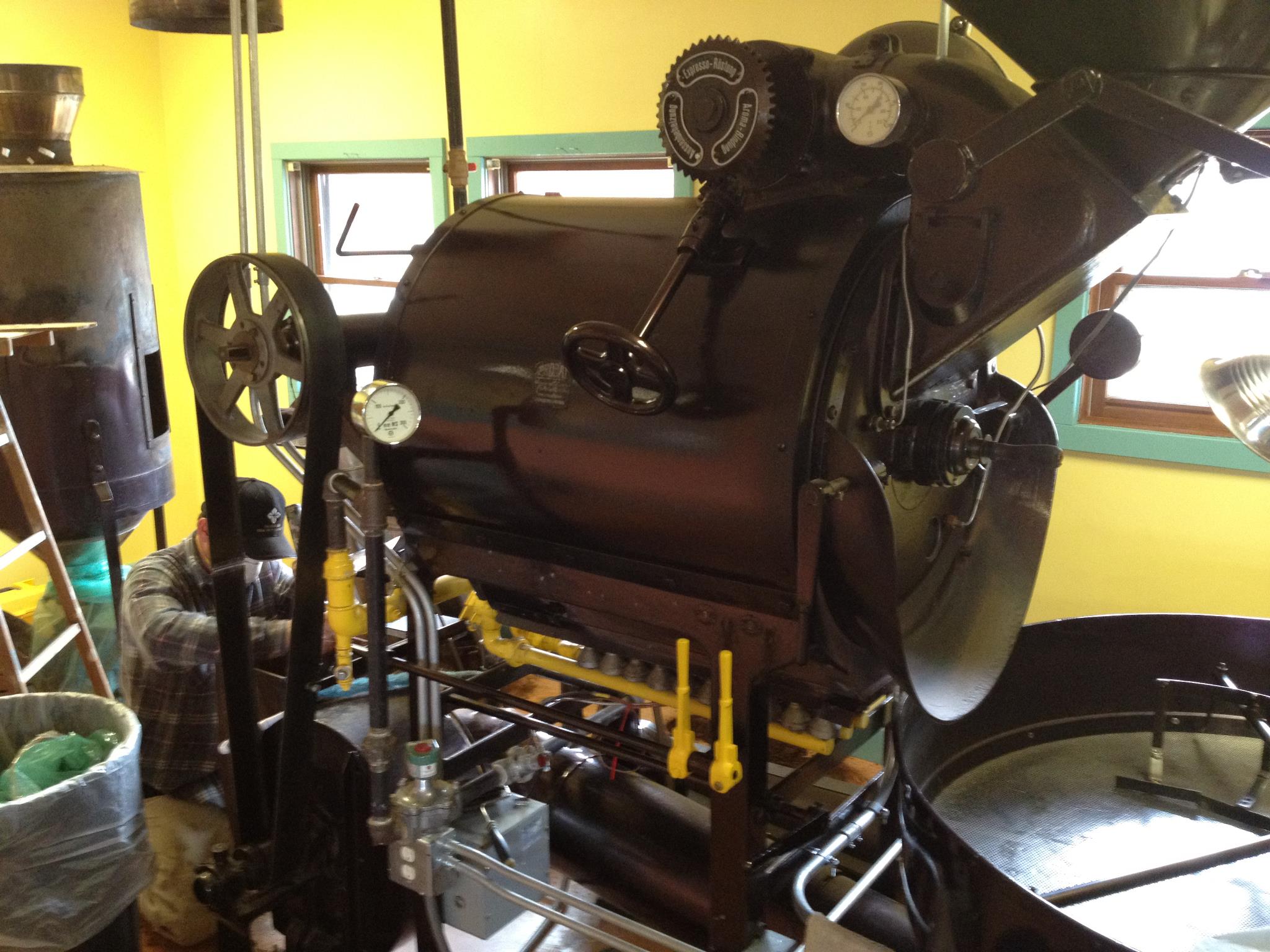

You KNOW we love data systems (NOTES, yes!!), but first, the machinery. “The roaster is gonna stay the same and that roaster we’ll never let go of,” says Nicholes. “It’s a super-rare German vintage roaster from the 1930s, manufactured by Probat. This one is a very unique size, a 30-kilo, a UG-30, and I don’t know if it was a prototype size or what, but it’s the only one we know of in operation in the U.S.

“We’ve invested in technology since the start. My partner developed a roast data system which lets us track every piece of information for every roast that we’ve ever done, essentially. Everything gets logged into a computer database and we’re essentially grabbing samples of all the roasts, doing insane quality control, cupping every batch that comes out of the roaster and as we find things we like and not, we go back and refer to those roast profiles and set up new target profiles, using subtle micro-adjustments to really bring out the best in each roast that we do. Every roast has a target roast profile as well as a target roast level. We have a roast analyzer which shoots infared (IR) light into both whole and ground coffee, measures the amount of light that reflects back, and gives us a number which tell us how done the coffee is. It’s like using a meat thermometer in a steak, tells you how done it is.

“As the coffee is coming out of the roaster, when a batch is done, the roaster will grab a sample, grind it up and analyze it to make sure it’s right where we want it, so we’re getting instantaneous feedback from the roaster on how those coffees are developing,” Nicholes continues. “Depending on weather, ambient air temps, humidity, and so on, the coffee is going to roast differently, but it’s a very tight correlation between how coffee tastes and how dark it is and there are certainly a lot of other factors that will affect that as far as how you got the coffee roasted: drum speed. We installed a special frequency control drive to give us control over how quickly our drum is rotating and another micro-tweak we did was add a motor to our fan, so we can control very precisely the amount of air-flow we are using throughout the whole roast profile and that lets us make pretty quick micro-adjustments throughout the roast as to how quickly we’re roasting the coffee.

Nicholes sums it up: “There’s a million variables that will affect the way the coffee tastes, but probably the biggest determinant is roast level–how cooked the coffee is. The other variables we’ve already accounted for, more or less: using air flow and drum speed to control how quickly we want the coffee to develop in the roaster and using the analyzer to give us a consistency and on-the-fly data to ensure those coffees are coming out way we want them. Otherwise, to get a good taste of a coffee takes two or three days before a coffee has chilled out enough to taste well and by that time you’ve roasted a lot of coffee.

Now, more from the data system originator, Semanchin: “It’s a total home-built roast log. It’s fully manual, an Excel® spreadsheet that has some fancy features built into it, but essentially is graphing the roasts real time, just like the ones you buy off the shelf do, but this one is customized for us completely.

“We have three thermocouples in our machine, so we can track data from all three of those and can easily go back and see any roast since inception, how we’re roasting coffees historically. Even our data logging is manual, so using a computer and an Excel® sheet but the roaster has to look at the time and temperature and input that data,” explains Semanchin. “This could be considered a distraction, but it also means the roaster is keeping integrated with the roast the whole time, is forced to do so. We’ve looked at automatic data loggers and considered it, but decided to stay with our system in house and there’s something to be gained there.

“Another piece of equipment we use religiously, Javalytics, roast analyzer,” says Semanchin. “It’s made in Madison, Wisc., and that’s how we analyze depth of roast. As soon as that coffee is cool, we’re grinding it up and analyzing it.

More About Kickapoo Sourcing Methodologies

You can do whatever with the roast and it’s still all about the beans. We know this, you know this, Kickapoo knows this.

“We’ve been jamming on our quality of sourcing. Through time, collaboration with friends and partners in the industry, we’re learning more about who to work with and where in the world, and how to dig in deeper with the producers to get the kind of quality we’re looking for,” says Nicholes. “Cooperative Coffees are still the bread and butter of our import program. Eighty-five percent of our coffee is sourced through them and most of those relationships within that co-op go back five-plus years.

“We’ve also started working on a smaller scale for coffees that are really sort of, I would say, in a class of their own. Sourcing a lot of those coffees, we’ve pioneered a bunch of our own projects in Ethiopia, Kenya and Honduras, figuring out ways of working with very, very small lots of 5-20 bags, usually from a single producer that are just crazy-awesome coffees.”

Time To Relax?

Even in idyllic Viroqua, Wisc., when you’re running a small business–especially a craft roaster–down-time can be hard to come by. Kickapoo fights this regularly by having created a four-day work-week situation for all. It doesn’t alleviate the stress, but does give the people that make up the company more time to decompress from what is a decidedly demanding job.

“For those of us who settled here, we love it,” says Semanchin. “I’m a transplant from Minneapolis, Caleb is from Madison, and some other folks here have moved from metropolitan areas. We’ve got folks who’ve been around and we’re all here for a reason. We appreciate the slower pace, the ability to be able to walk to work. It’s a lifestyle fully integrated with the business and I think we’re appreciating our time here, loving our work in coffee, and appreciating our time off with family, going camping with the kids [Semanchin has two, aged six and three] or whatever it might be.

And, that is the continuing tale of Kickapoo Roasters in Viroqua, Wisc. As we mentioned in the beginning, you can read more about the founding of the company and about both owners in our original blog post RE: Kickapoo Coffee. Now, it’s just up to you to stop by Wormhole and enjoy.